Shenzhen CKT Print Co.,Ltd

Offered R&D Service of all Printing and Packaging Items:

The packaging industry is constantly evolving, driven by emerging technologies, market trends, and consumer demands. Research and Development (R&D) play a crucial role in driving innovation, sustainability, and efficiency within the packaging sector. Here are some key areas of research and development in the packaging industry:

Sustainable Packaging Solutions:

R&D efforts focus on developing eco-friendly and sustainable packaging materials and solutions. This includes exploring renewable and biodegradable materials, reducing packaging waste, and finding alternatives to single-use plastics. Research also focuses on optimizing packaging designs to minimize environmental impact throughout the lifecycle of the product.

Intelligent and Active Packaging:

R&D teams work on integrating smart technologies into packaging to improve functionality and enhance consumer experiences. This includes intelligent packaging solutions that provide real-time information about product quality, freshness, and safety. Active packaging systems utilizing oxygen scavengers or moisture absorbers help extend product shelf life and maintain product integrity.

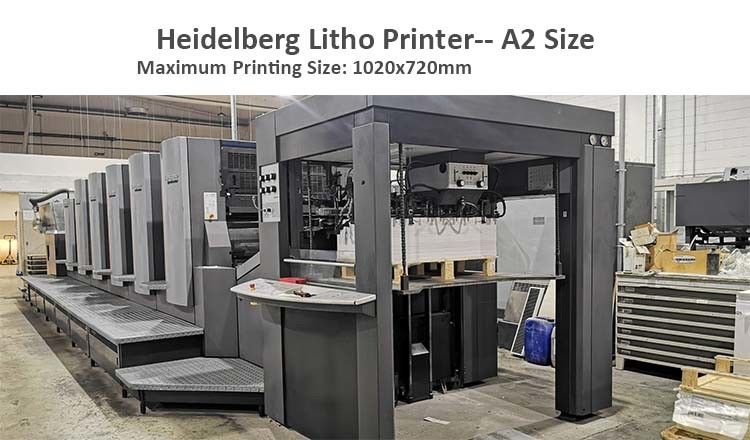

Advanced Manufacturing Processes:

R&D efforts are directed towards enhancing manufacturing processes in the packaging industry. This includes exploring automation, robotics, and artificial intelligence to optimize production efficiency, reduce costs, and improve quality control. Research also focuses on developing new printing techniques, surface treatments, and finishing processes to create visually appealing and high-performance packaging.

Nanotechnology in Packaging:

R&D teams explore the potential of nanotechnology in packaging to improve functionalities like barrier properties, antimicrobial coatings, and enhanced mechanical strength. Nanomaterials and nanostructures are being studied for their potential to enhance packaging performance and meet specific product requirements.

Smart Labeling and Tracking Systems:

R&D efforts are dedicated to developing advanced labeling and tracking systems for improved traceability, supply chain efficiency, and anti-counterfeiting measures. This includes research on RFID (Radio Frequency Identification), NFC (Near Field Communication), and QR code technologies to enable seamless product identification, authentication, and tracking.

Packaging Safety and Quality:

R&D initiatives focus on ensuring packaging safety and quality by developing improved testing methods and standards. This includes research on migration of substances from packaging materials to ensure compliance with health and safety regulations. R&D also aims to enhance packaging integrity and durability through innovative materials and structural designs.

Consumer Insights and Market Trends:

R&D teams conduct market research and analyze consumer insights to identify emerging trends and demands in packaging. Understanding consumer preferences helps in the development of innovative packaging designs, convenience features, and interactive packaging elements that resonate with target audiences.

Regulatory Compliance:

R&D efforts are dedicated to staying abreast of changing regulations and standards in the packaging industry. Research focuses on ensuring packaging compliance with international regulations related to food safety, product labeling, environmental impact, and recycling.

By investing in research and development, the packaging industry continues to evolve and meet the changing needs of businesses, consumers, and the environment. R&D initiatives drive advancements in sustainable practices, product integrity, functionality, and aesthetics, shaping the future of the packaging industry.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!